BMFRG | Building a conceptual framework for manufacturing circular garments in the UK

Sustainable materials Circular supply chain Consumer experience

Overview

Together with the team of supply chain experts, social designers and material scientists from the Burberry Material Futures Research Group (current Textiles Circularity Centre) at the RCA, I investigated the UK textile and clothing industry and trends. I proposed a conceptual framework for the UK-based production and consumption of textiles made of the local food industry by-products and waste.

Context

UK

Duration

2019

The Problem

The fashion sector in the UK is responsible for over 1MT of material going to landfill and incineration each year. The country imports most of the apparel and textiles, having little material independence and control over the amount of waste produced.

The Goal

To repatriate textile production to the UK by designing and developing a circular and transparent supply chain of materials made of locally abundant feedstock.

The team focused on wheat straw as the largest UK agri-food industry by-product and its suitability for textile fabrication

The Process

Research Question 1: What are the current challenges and opportunities of the UK textiles industry?

Method 1: Desk research on the UK textiles and clothing industry and trends.

Duration: 2 weeks

According to Business Insider, the equivalent of one garbage truck full of clothes is burned or dumped on a landfill site every second. Photo: Mufid Majnun (Unsplash)

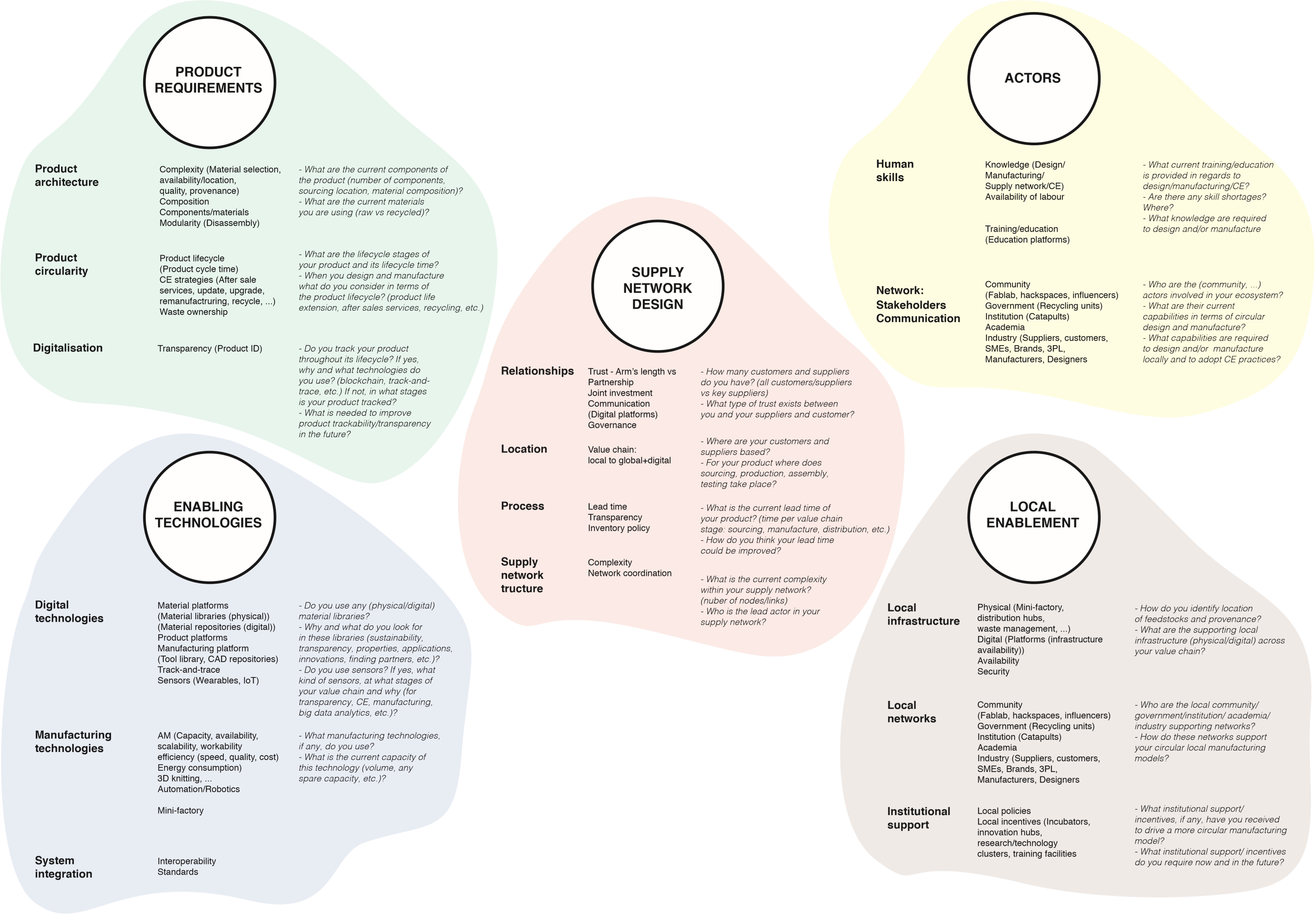

Research Question 2: What technologies and business models are needed to support a transparent circular textiles supply chain? (in collaboration with Dr Patrick Hennelly)

Method 2: Semi-structured interviews with distributed manufacturing practitioners.

Participants: Representatives from 14 UK-based SMEs.

Duration: 4 weeks

Method 3: Development of the conceptual framework of distributed manufacturing for circular textiles in the UK context.

Duration: 2 weeks

Method 4: Validation of the developed framework with distributed manufacturing experts.

Participants: 10 professionals from industry and academia.

Duration: 4 weeks

We evaluated a long list of features of circular economy and distributed manufacturing to find out which of them need to be included in the final version of our framework

Research Question 3: How to ensure the sustainable development of the long-term multi-partner project? (in collaboration with the whole team)

Method 5: Contribution writing the grant application which successfully secured the group a grant of £5.4m from UKRI.

Duration: 4 weeks

Method 6: Co-organisation of the public exhibition and presentation of the research insights at the symposium during the London Design Festival 2019.

Duration: 4 weeks

A half-day symposium and an exhibition of the feasibility phase during the London Design Festival included short films, displays, material samples and tangible prototypes.

The Outcomes

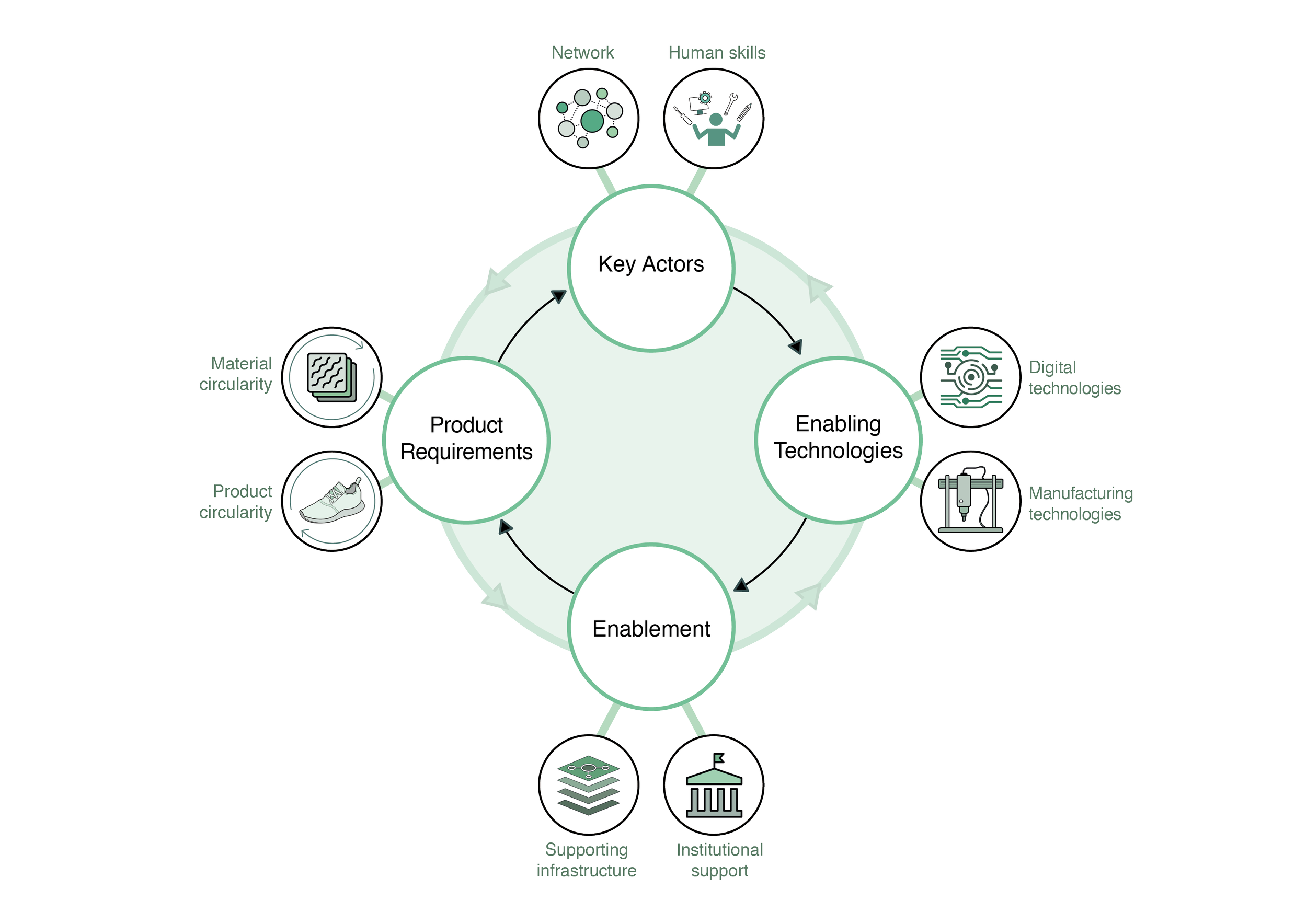

A conceptual framework which provides theoretical know-how for the development of the circular and transparent supply chain of UK-made textiles.

Established partnerships between the UK apparel SMEs and the research group for future collaborations.

The conceptual framework includes drivers, attributes and challenges of distributed manufacturing and their considerations along the product life cycle to enable the circular economy

Credits to the team: Prof Sharon Baurley, Dr Patrick Hennelly, Dr Bruna Petreca, Dr Miriam Ribul, Prof Steve Evans