LENSin | Exploring the opportunities of networked production to improve product-service systems

Future scenarios Sustainable manufacturing Design tool

Overview

During the three-year research project which gained me a PhD degree, I looked at the near-future trends of distributed manufacturing (DM) and how they could be applied to designing sustainable product-service systems (PSS). I have built, tested and refined a future scenario-based idea generation toolkit to help companies and designers create product-service systems.

Context

UK, Brazil, China

Duration

2016-2019

The Problem

By mixing products and services, companies can differentiate their offerings and have a competitive advantage. However, the development of product-service systems is still hindered by organisational and cultural challenges, the need for long-term strategic thinking and a lack of supportive regulations. The focus of this research project was to find innovative ways of creating and maintaining sustainable product-service systems in various contexts.

The Goal

To facilitate the design of product-service systems through distributed manufacturing enabled by the latest technologies (e.g., additive manufacturing, smart factory, etc.).

Distributed networks can potentially be more resilient, responsive and scaleable than their centralised counterparts. Illustration: Baran (1964)

The Process

Research Question 1: What barriers prevent companies and consumers from successful product-service systems implementation and acceptance?

Method 1: Desk research - understanding the most common implementation challenges of product-service systems.

Duration: 2 weeks

Reckless consumer behaviour with products they do not own is one of the many issues encountered by product-service systems providers. Photo: Daisy Chen (Unsplash)

Research Question 2: What are the characteristics of distributed manufacturing?

Method 2: Desk research - collecting benefits, limitations and near-future trends of distributed manufacturing.

Duration: 3 weeks

Method 3: Semi-structured interviews with distributed manufacturing experts.

Participants: 10 professionals from industry and academia.

Duration: 4 weeks

Distributed manufacturing is a shift from centralised mass production to small-scale local production, reminiscing the pre-Industrial Revolution era but enhanced with the Internet

Research Question 3: What is the potential of distributed manufacturing to address the implementation barriers of sustainable product-service systems?

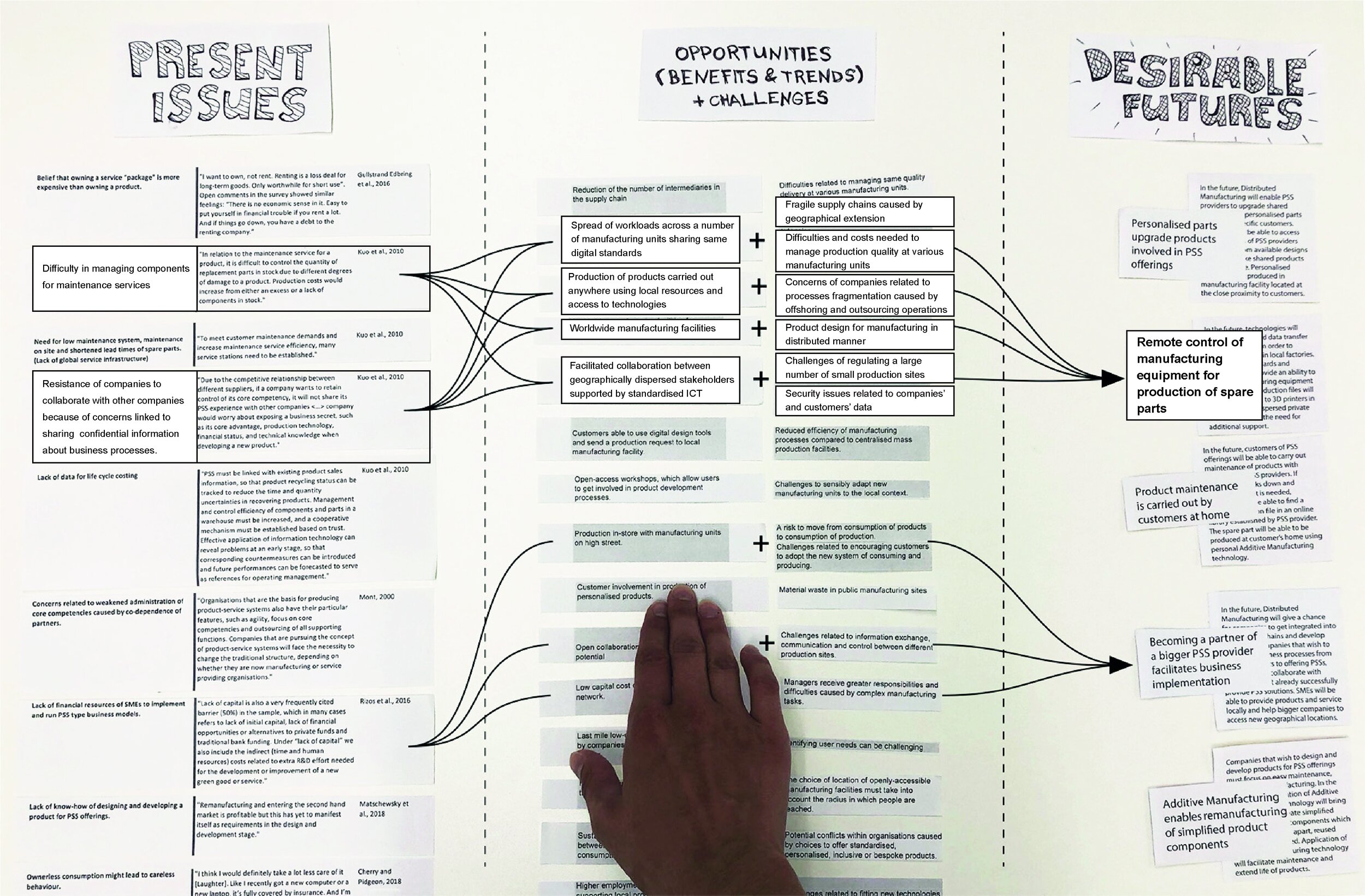

Method 4: Analysis of early research findings and their integration in the near-future scenarios of distributed manufacturing-enabled product-service systems design.

Duration: 2 weeks

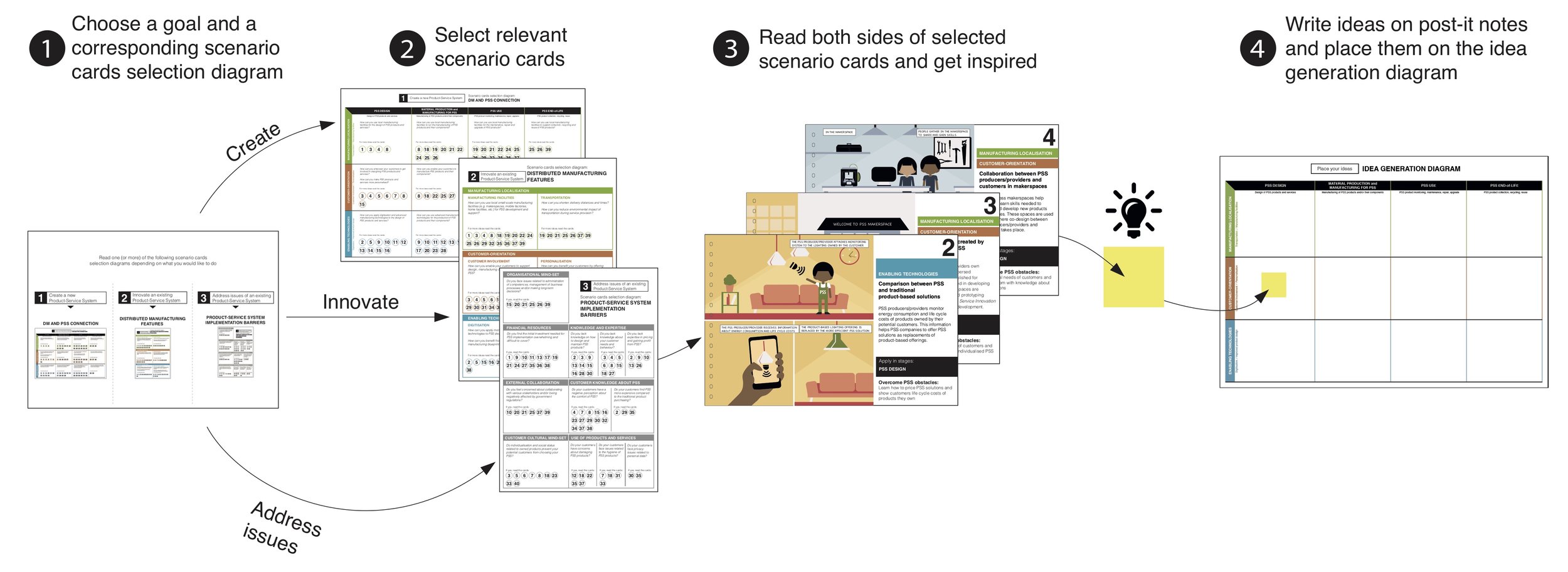

Method 5: Integration of the near-future scenarios into the first version of the PSS+DM Toolkit.

Duration: 4 weeks

Near-future scenarios have been built using the cognitive mapping method, which helped visualise the potential relationships between the PSS barriers and DM opportunities

Research Question 4: How to enable designers and industrial companies to consider distributed manufacturing when creating or improving product-service systems?

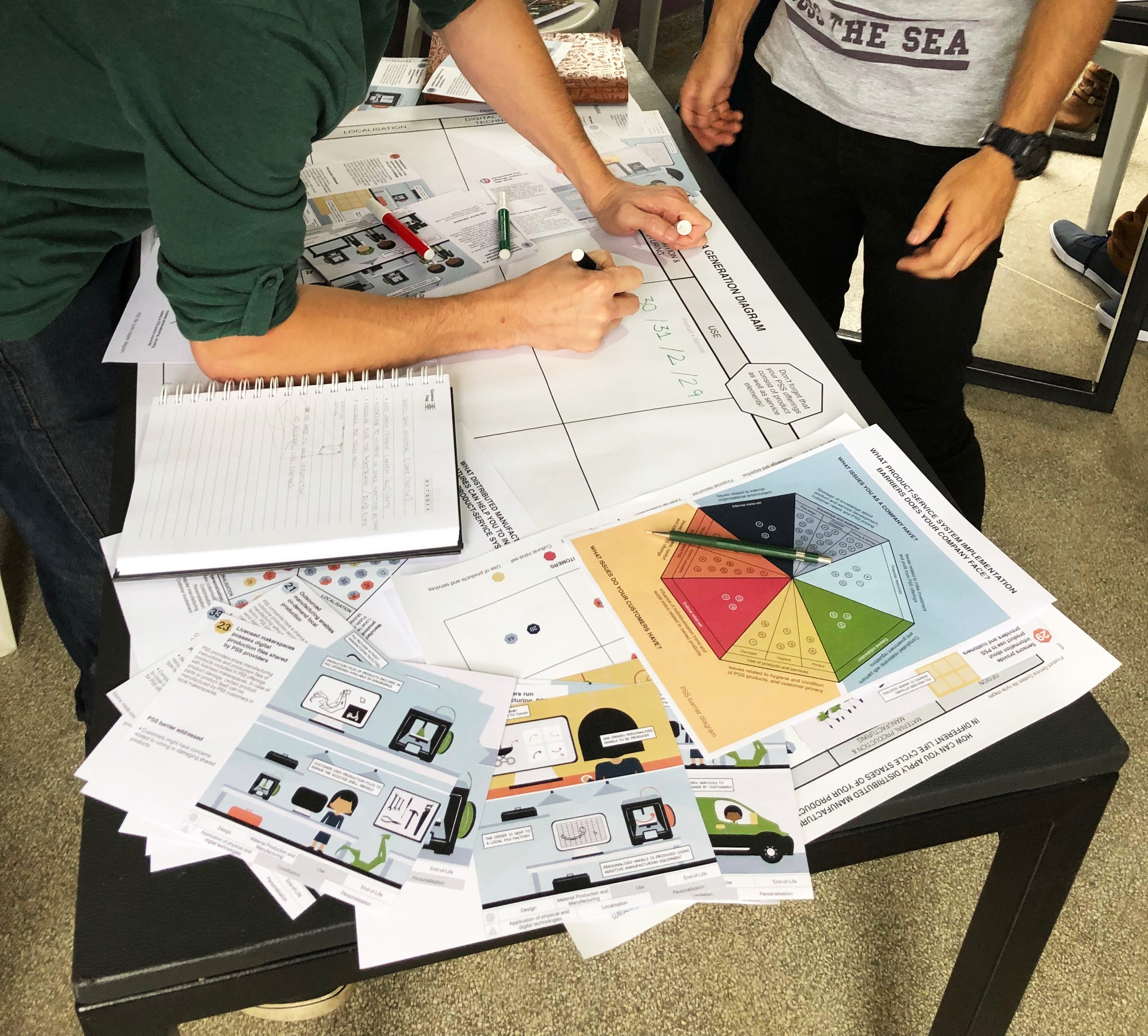

Method 6: Four rounds of idea generation workshops designed to test, evaluate and revise the PSS+DM toolkit.

Participants: 94 designers and employees of industrial companies, involved in design and innovation processes.

Duration: 5 weeks

Method 7: Development of the final version of the toolkit based on the data collected during the testing workshops.

Duration: 3 weeks

Participants of the toolkit’s testing workshops had to design sustainable product-service systems and later evaluate the toolkit’s completeness, effectiveness and usability

The Outcomes

An open-source idea generation toolkit which encourages future-oriented thinking towards the solutions for sustainable product-service systems.

40 near-future scenarios of distributed manufacturing.

Increased awareness of a sustainable mix of products and services, their design and implementation.

The PSS+DM Toolkit supports the development of brand-new product-service systems and helps improve the existing ones.

Credits to the team: Dr Fabrizio Ceschin, Prof Aguinaldo dos Santos, Prof Carlo Vezzoli, Prof Liu Xin, Prof David Harrison, Dr Eujin Pei

Interested in the PSS+DM Toolkit ? Drop me a line: aine@petrulaityte.com

Publications

Petrulaityte, A., Ceschin, F., Harrison, D. and Pei, E. (2020) 'Applying distributed manufacturing to product-service system development: A set of near-future scenarios and a design tool'. Sustainability, 12 (12).

Petrulaityte, A. (2019). ‘Distributed manufacturing applied to product-service systems: a scenario-based design toolkit’. PhD thesis, Brunel University London, UK.

dos Santos, A., Vezzoli, C., Garcia Parra, B., Molina Mata, S., Banerjee, S., Kohtala, C., Ceschin, F., Petrulaityte, A., Garcez Duarte, G., Burmeister Dickie, I., Balasubramanian, R. and Xia, N. (2021) ‘Distributed Economies’. In: Vezzoli, C., Garcia Parra, B. and Kohtala, C. (eds) Designing Sustainability for All: The Design of Sustainable Product-Service Systems Applied to Distributed Economies. London: Springer.

Petrulaityte, A., Ceschin, F., Pei, E. and Harrison, D. (2019) 'Distributed manufacturing applied to product-service systems: A set of near-future scenarios’. 3rd LeNS World Distributed Conference: Designing Sustainability for All. Milano, Mexico City, Beijing, Bangalore, Curitiba, Cape Town. 3 - 5 April. Edizioni POLI. Design.

Petrulaityte, A., Ceschin, F., Pei, E. and Harrison, D. (2019) 'A design toolkit to integrate distributed manufacturing into product-service systems development’. 3rd LeNS World Distributed Conference: Designing Sustainability for All. Milano, Mexico City, Beijing, Bangalore, Curitiba, Cape Town. 3 - 5 April. Edizioni POLI. Design.

Petrulaityte, A., Ceschin, F., Pei, E. and Harrison, D. (2018) 'A design tool to apply distributed manufacturing principles to sustainable product-service system development'. Design Research Society (DRS) 2018. Limerick, Ireland. 25 - 28 July.

Petrulaityte, A., Ceschin, F., Pei, E. and Harrison, D. (2017) 'Supporting sustainable product-service system implementation through distributed manufacturing'. The 9th CIRP Industrial Product-Service System Conference: Circular Perspectives on Product/Service-Systems. Denmark. 19 - 21 June. Elsevier BV.